ISBM Technology

INJECTION STRETCH BLOW MOLDING

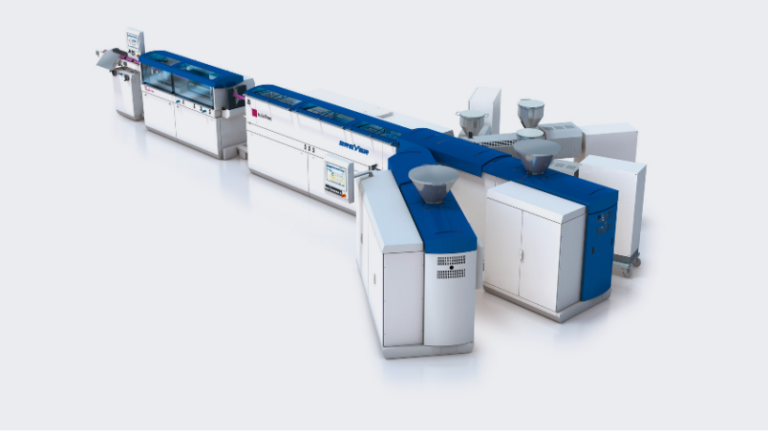

A single-stage platform built on versatility

to support all your packaging needs.

Capabilities

Our manufacturing sites use the latest single-stage machine platform to produce containers ranging in size from 5 milliliters up to 2 liters.

Each facility has a common machine platform with various machines able to support beta testing tools and smaller cavitation production tools, up to 40 cavities for your larger volume projects. From a custom design preform specific to your bottle shape to designing only blow cavities utilizing one of our many stock preforms, Axium has the flexibility and is ready to support all your packaging projects.

Materials

- Polyethylene Terephthalate – PET

- Co-Polyester

- Polypropylene – PP

- Up to 100% PET PCR (Post Consumer Resin)

Markets Served

Personal Care

& Beauty

& Beauty

NEUTRACEUTICALS

HOUSEHOLD CHEMICAL

FOOD &

BEVERAGE

BEVERAGE

Healthcare

& OTC

& OTC

Stretching the limits through Injection Stretch Blow Molding

ISBM Advantages

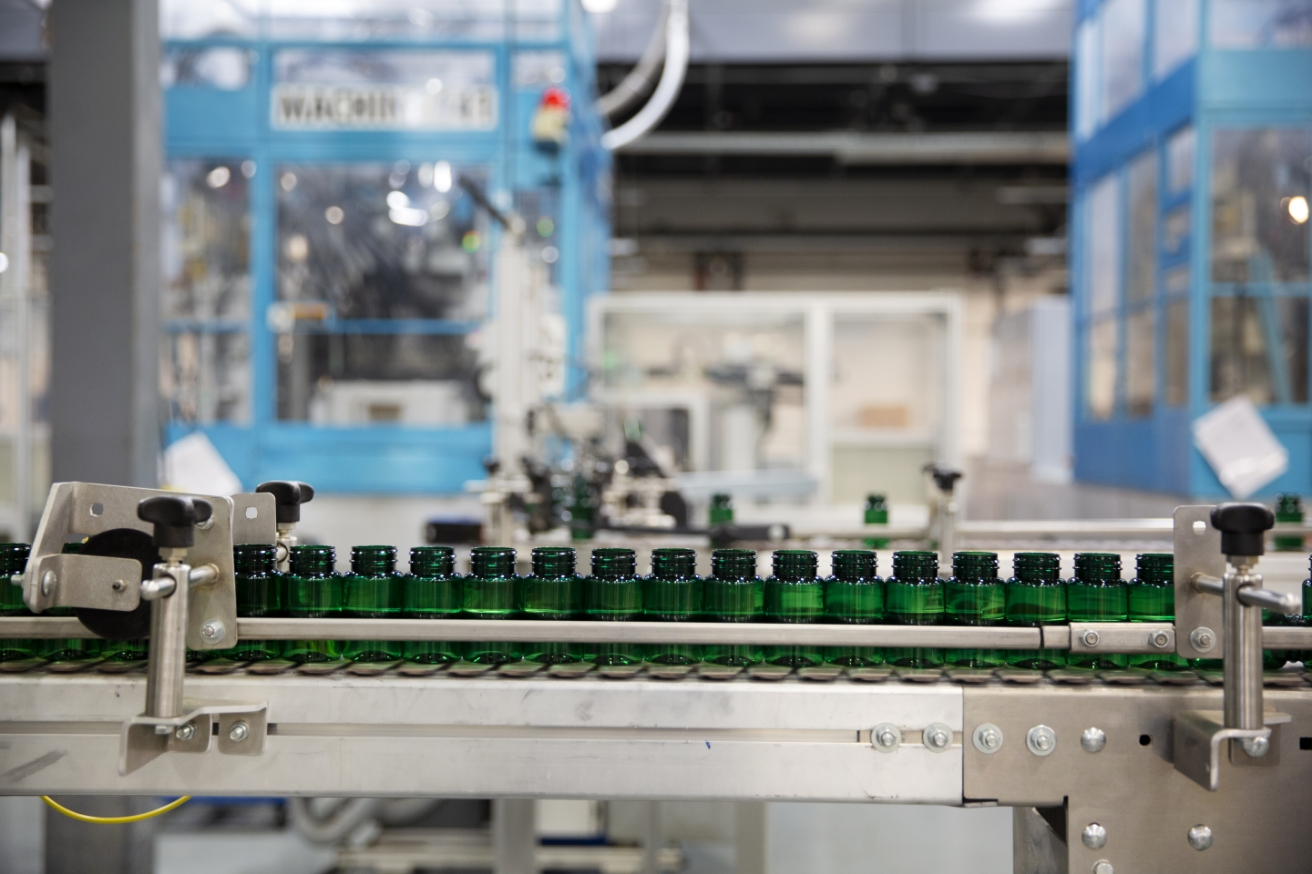

- High clarity containers

- Ultra thin to heavy containers depending on resin selection

- Injection molded neck tolerances

- Child resistant and plug seal neck finish designs

- Low or high cavitation up to 40 cavities